Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Sanitary Flow Cut Shut-off Valves can be actuated either manually or pneumatically. The series of Sanitary Pneumatic Flow Division Valves makes major medium reaching the purpose of revising or end stop, because the good sealability and cleanability, they are extensively use different sanitary industry areas.

They can be fitted with control tops and proximity. It is widely applied to many filed,such as beer,beverage,dairy food,fruit juice,pharmacy,biological etc.

Sanitary Flow Cut Shut-off Valves have two types valves, including of cut-off type and reversing types. The cut-off type can be made of two or three pipeline connector. The reversing type can be made of three to five pipeline connector. Their variety fully satisfied the demands of market.

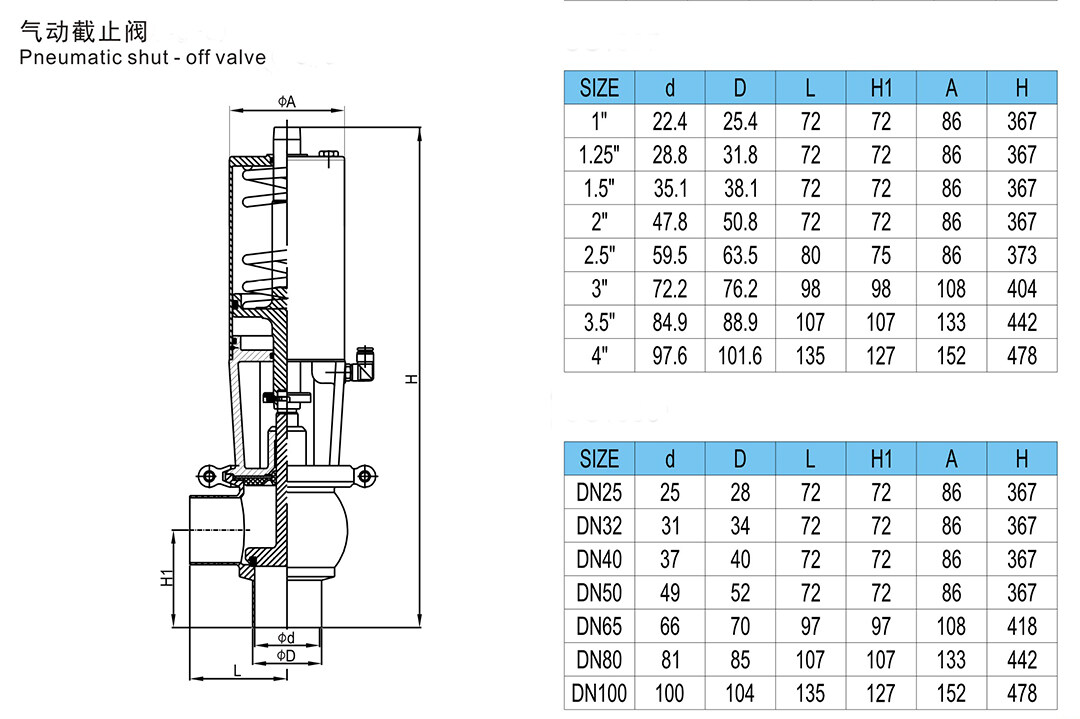

Product parameter

| Standard | SMS,DIN,3A | |

| Material Contact Parts | SS304/SS316L(1.4301/1.4404) | Provided with material inspection report |

| Material Non-contact Parts | SS304(1.4301) | |

| Size | 1/2”-4”, DN10-DN100 | |

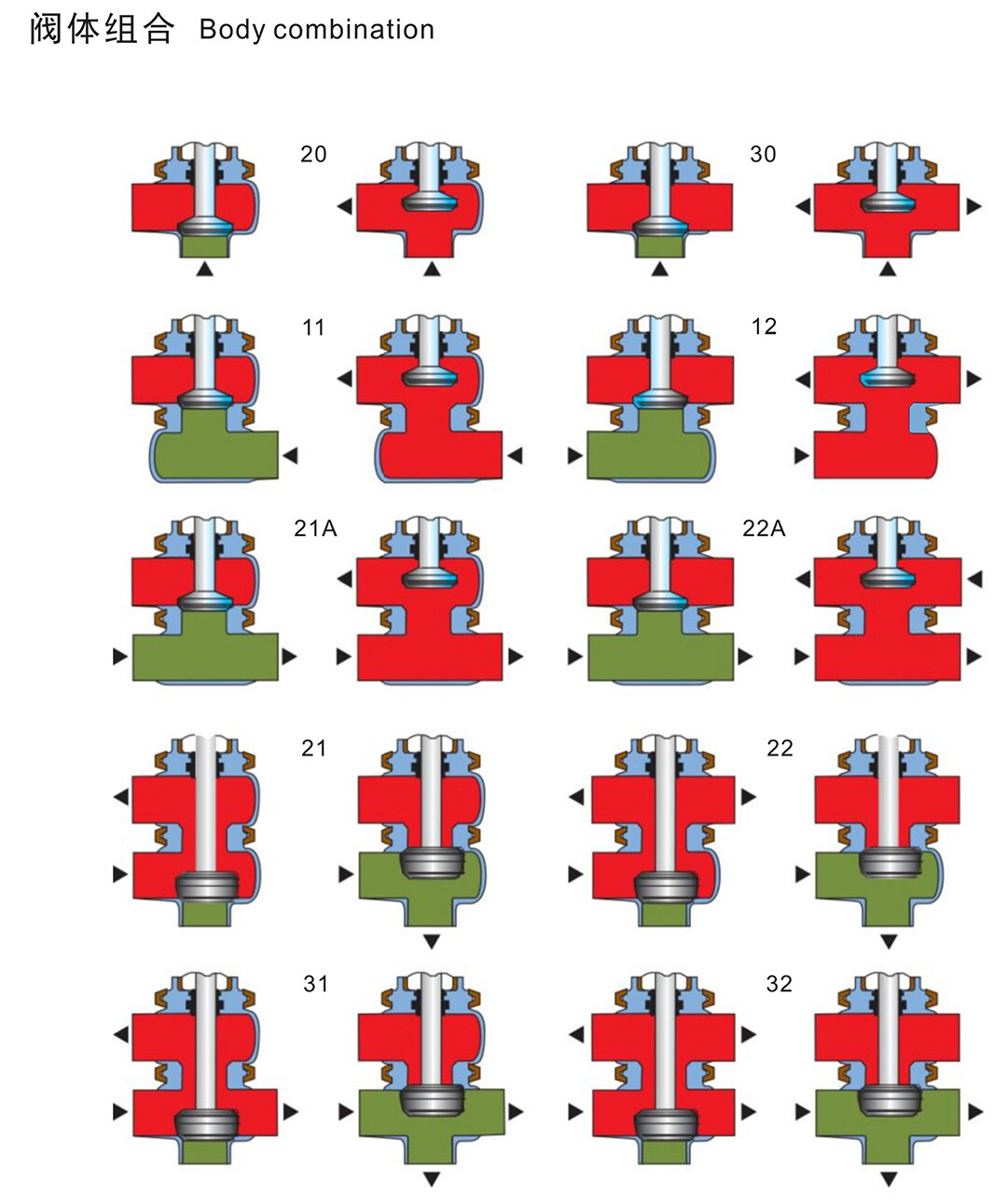

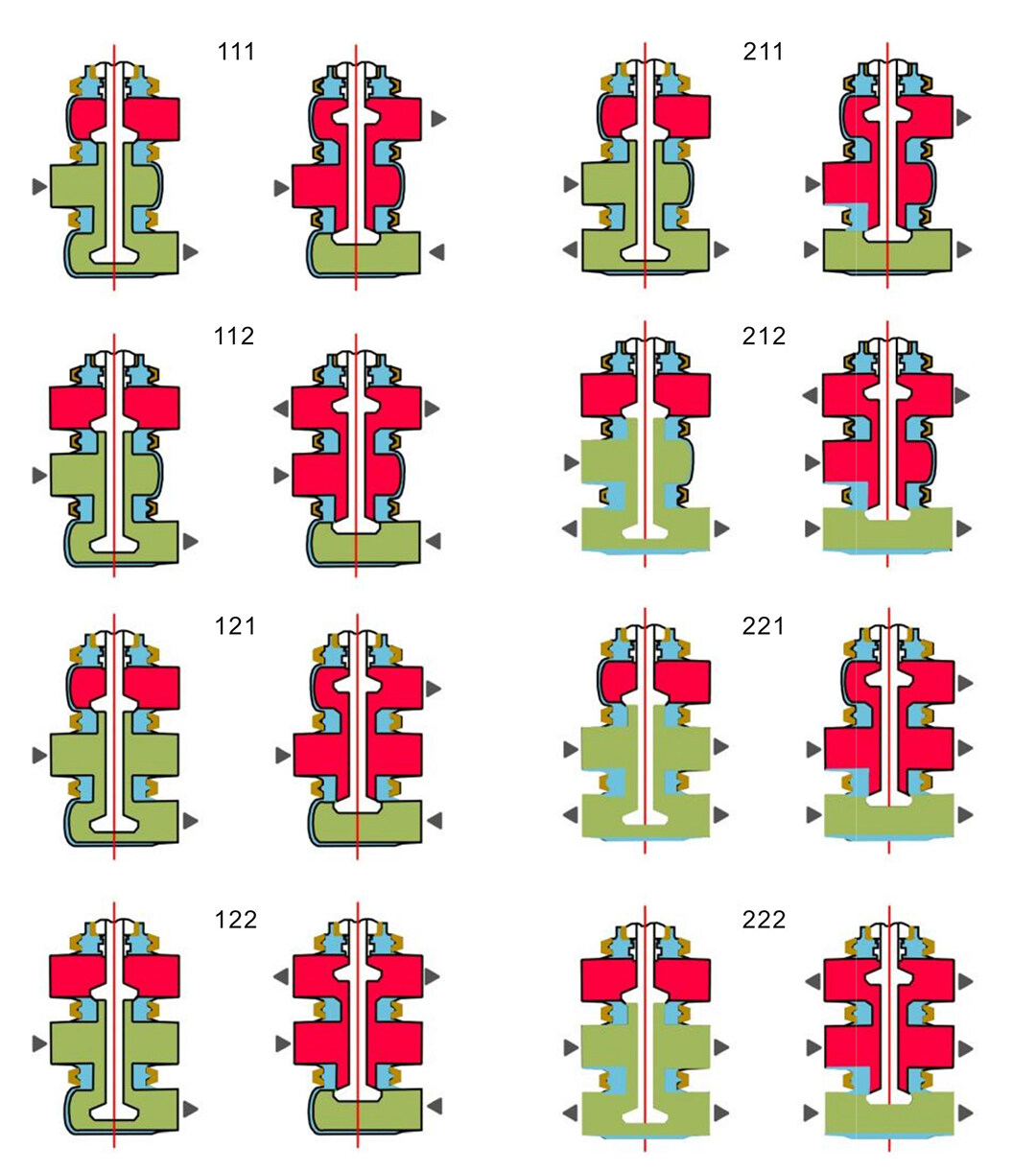

| Body Combination |

20 Model,30 Model,11 Model,12Model,21A Model,22A Model,21 Model,22 Model,31Model,32 Model 111 Model,112 Model,121 Model,122Model,211 Model,212 Model,221 Model,222 Model |

|

| Connection | Butt-weld,Tri-clamp,Male Thread,Female-Male Threaded,Union,Weld-Thread,Flang | |

| Seal Material | Silicone,EPDM,FKM,Buna. All seals material comply with FDA21CFR117.2600 | |

| Power Option | Manual Operated | |

| SS Pneumatic Actuator | ||

| Position Sensor, C-top Controller, C-top Controller (AS-I) | ||

| Working Pressure | ≤10bar(145psi) | |

| Supply Pressure for Air Actuator | ~8(72.52psi~116psi) | |

| External Surface Treatment | Ra32~64uin(0.8~1.6um) | |

| Internal Surface Treatment | Ra16~32uin(0.4~0.8um) | |

Installation and maintenance of the sanitary pneumatic TC LL diverter valve with C-top are hassle-free due to its user-friendly design. It can be easily installed and disassembled, saving you valuable time and effort. Its modular construction allows for quick and easy maintenance, ensuring minimal downtime and maximum efficiency.

Product drawing

Product Features

Product Features

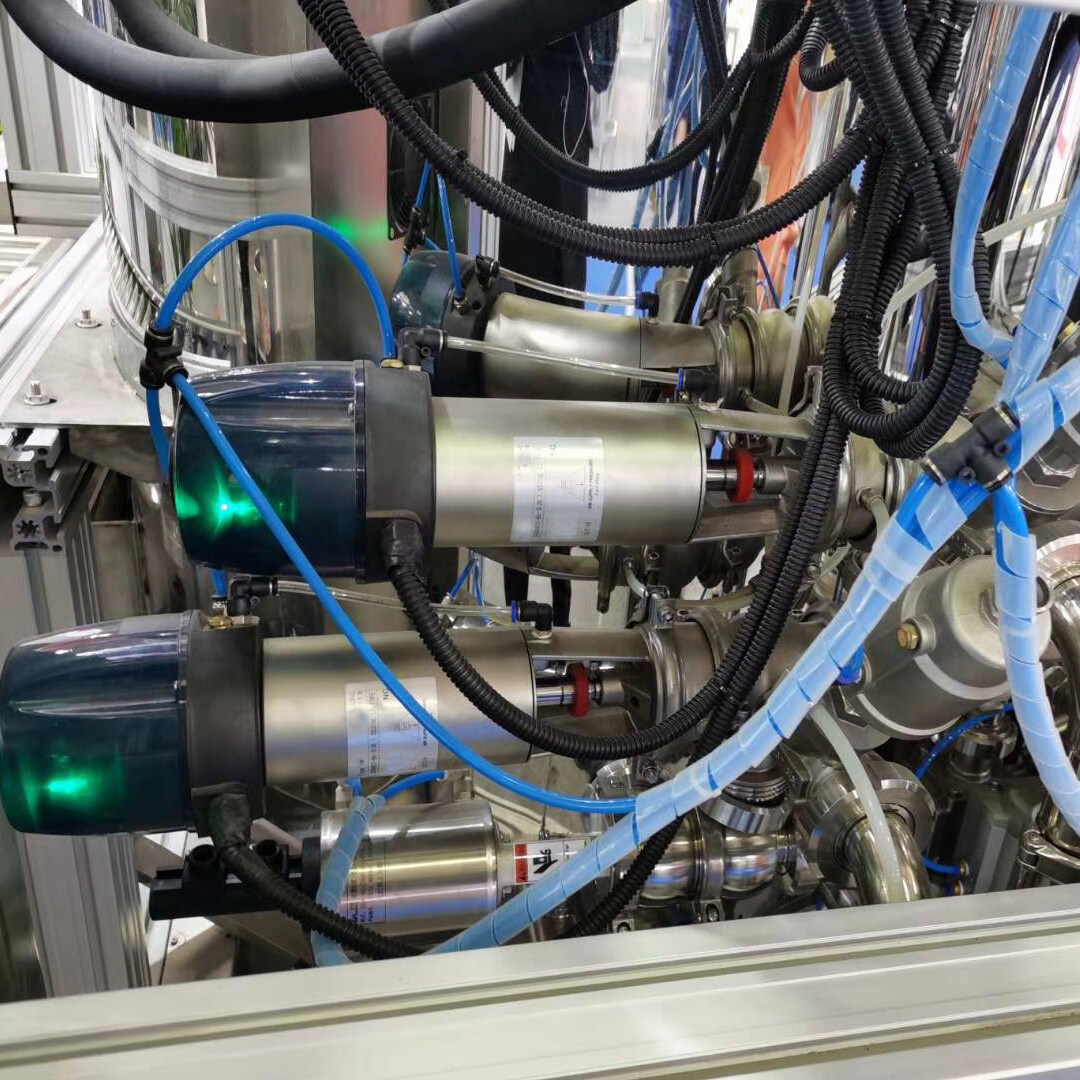

Application scenario

Product Advantages

1.Enhanced Process Control: The advanced actuation technology and intelligent monitoring system of the valve enable precise and reliable process control, ensuring consistent product quality and reducing waste. By maintaining optimal flow rates and pressure levels, the valve helps to minimize variations in the process, reducing waste and improving overall efficiency.

2.Improved Productivity: With its enhanced cleanability and modular design, the valve minimizes downtime for cleaning and maintenance, maximizing production uptime and overall productivity. Its enhanced cleanability features, such as smooth surfaces and minimal dead spaces, make it easier to clean and sanitize, reducing the time required for cleaning procedures

3.Cost Savings: The integrated control system and advanced actuation technology optimize energy consumption and reduce operational costs. Additionally, the valve’s durability and reliability minimize the need for frequent replacements or repairs, resulting in long-term cost savings.

Applications

Cosmetics and Personal Care Industry: The sanitary diverter valve is widely employed in the cosmetics and personal care industry for diverting fluids like lotions, creams, and fragrances. It enables efficient routing of different formulations to different packaging lines, ensuring smooth production processes.

Biotechnology and Life Sciences: In biotechnology and life sciences applications, the valve plays a vital role in diverting fluids during fermentation, cell culture, and purification processes.